What factors will affect the production accuracy of Perforated Metal

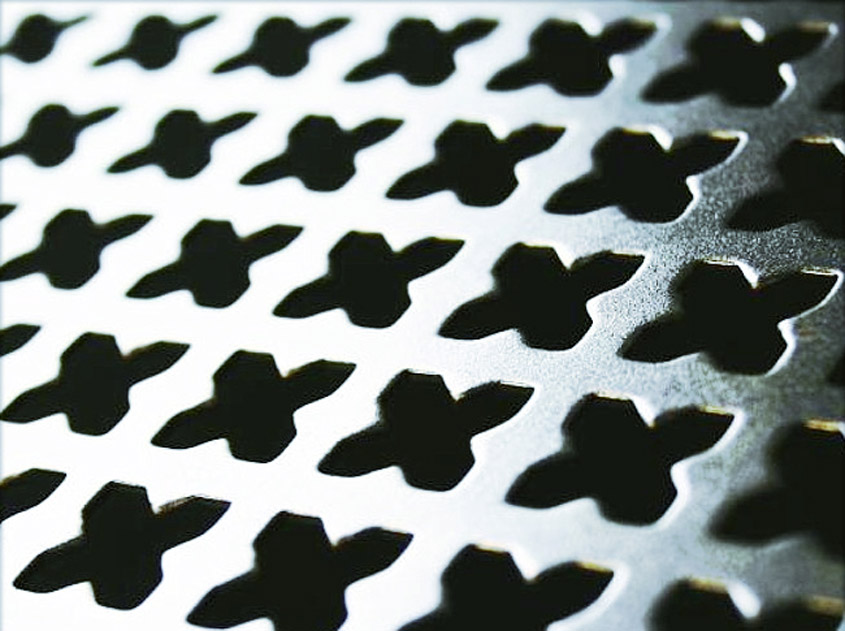

What factors will affect the production accuracy of Perforated Metal?

1. Perforated mesh mold mesh clearance: During the development of the punched mesh mold, the mesh must be uniform and reasonable; otherwise, it will cause traces on the fracture surface, and in severe cases, it may even cause tearing. happened.

2. Perforated Metal die thickness: The thickness of the die can also have a certain effect on the punching net product, and if the punching pressure is too large, it will also cause the board to crack. It can even damage the punching machinery.

3. The material properties of the punching net mold: ordinary metal sheet should be used as the product mold, so that not only can improve the accuracy of the product, but also maintain its steady state during the stamping process, and it is not prone to any damage; Conversely, strong or weak hardness will cause certain defects to the product, which in turn will affect the quality of the product.

-

Caja de gaviones 08. 03, 2021

Caja de gaviones 08. 03, 2021 Dos usos comunes de la valla de malla ciclónica 04. 01, 2021

Dos usos comunes de la valla de malla ciclónica 04. 01, 2021 -

Triangle iron European guardrail 09. 29, 2020

Triangle iron European guardrail 09. 29, 2020 Learn about metal decorative mesh 09. 24, 2020

Learn about metal decorative mesh 09. 24, 2020 How to choose high-quality metal decorative mesh 09. 24, 2020

How to choose high-quality metal decorative mesh 09. 24, 2020

- Teléfono: +86 311 83077076

- Correo electrónico: natalia@qunkun.net

- Skype: qunkunsales01

- WhatsApp: +8615533680669

- Añadir: No 69-70, el parque industrial de filtros del condado de Anping, Hebei China