Regular maintenance and inspection of stainless steel mesh products

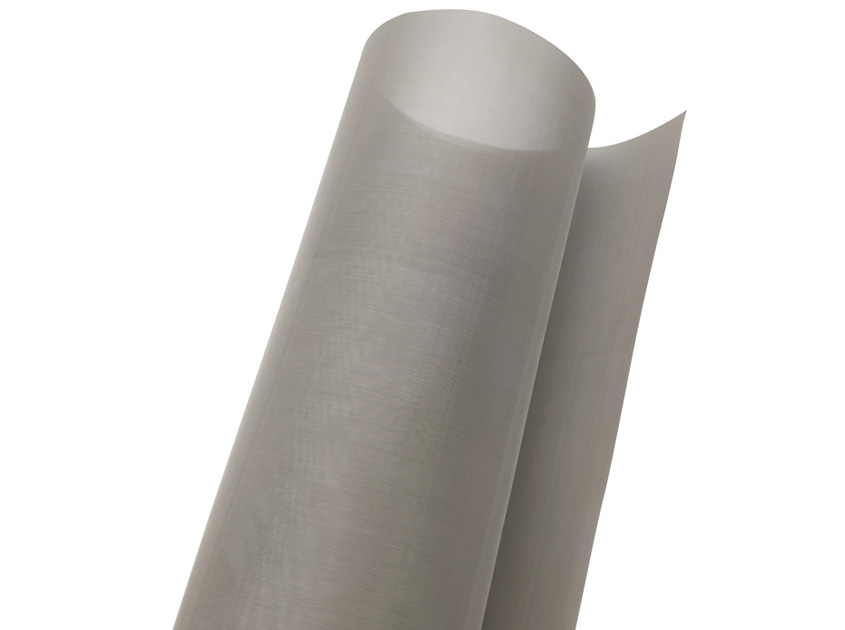

Stainless steel mesh products need to be regularly maintained and inspected. There are many kinds of products in daily maintenance, generally including daily maintenance, regular maintenance, regular inspection and accuracy inspection, basic work of folding maintenance during the routine maintenance of stainless steel mesh belt.

1. Plain weaving: Plain weaving is a weaving method in which each warp thread crosses each weft thread up and down, the diameter of the thread is the same as that of the weft thread, and the warp and weft threads form a 90 degree angle. The plain weave mesh is relatively square, with uniform mesh size. Each warp thread crosses each weft thread up and down. The diameter and diameter of the weft thread are the same, and the warp and weft threads form a 90-degree angle.

2. Twill weave: A weaving method in which each warp thread crosses above and below every 2 weft threads, and each weft thread crosses above and below every 2 diameter threads.

3. Dense weave: The silk diameter of the warp and weft is different, and the number of meshes is also different. The warp yarns are in the longitudinal direction and the weft yarns are in the width direction. Dense mesh is divided into mat type net plain weave and mat type net twill weave.

4. Mat type net twill weaving: A weaving method in which each diameter wire crosses above and below every 2 weft threads, and each weft yarn crosses over and above every 2 diameter threads.

5. Two-filament Dutch weaving: This weaving is very similar to twill Dutch weaving. There are two weft threads, which can be stacked close to the warp threads.

-

Caja de gaviones 08. 03, 2021

Caja de gaviones 08. 03, 2021 Dos usos comunes de la valla de malla ciclónica 04. 01, 2021

Dos usos comunes de la valla de malla ciclónica 04. 01, 2021 -

Triangle iron European guardrail 09. 29, 2020

Triangle iron European guardrail 09. 29, 2020 Learn about metal decorative mesh 09. 24, 2020

Learn about metal decorative mesh 09. 24, 2020 How to choose high-quality metal decorative mesh 09. 24, 2020

How to choose high-quality metal decorative mesh 09. 24, 2020

- Teléfono: +86 311 83077076

- Correo electrónico: natalia@qunkun.net

- Skype: qunkunsales01

- WhatsApp: +8615533680669

- Añadir: No 69-70, el parque industrial de filtros del condado de Anping, Hebei China